Forming Technology

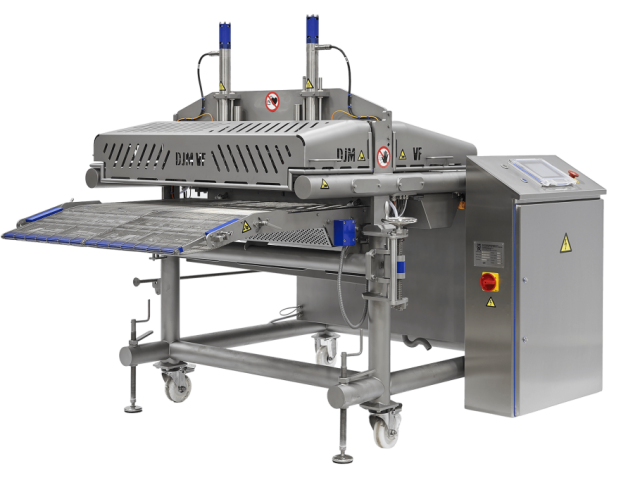

VacForm machines are ideal for producing burgers, cutlets, chicken nuggets,…

Product details

VacForm machines are ideal for producing burgers, cutlets, chicken nuggets,…

Product details

DJM’s co-extrusion machines are ideal for the production of (filled)…

Product details

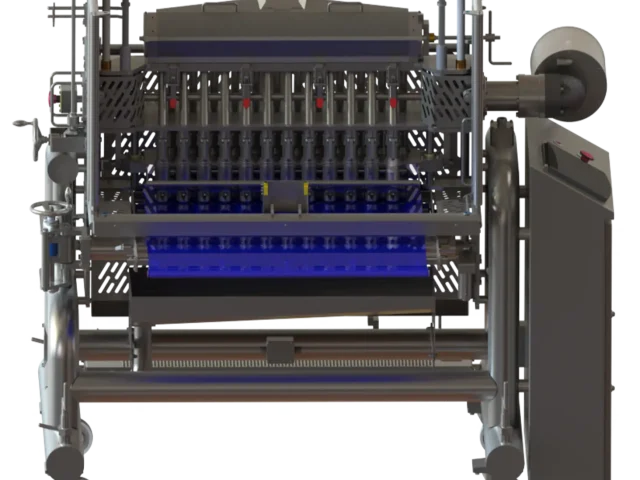

Unprecedented flexibility combined with high production capacity are some of…

Product details

Unprecedented flexibility in combination with a high production capacity are…

Product details

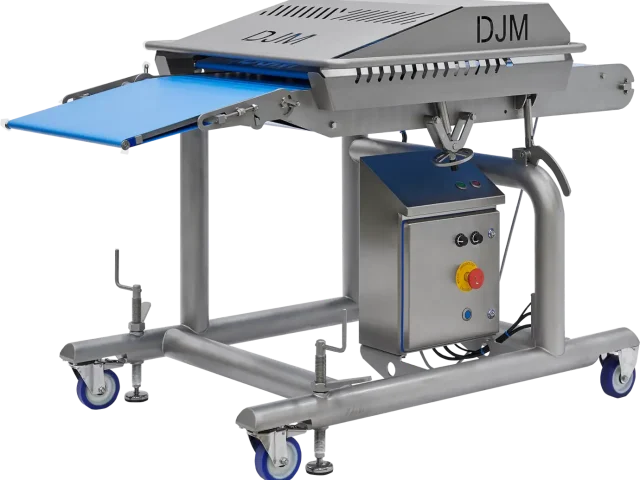

DJM has developed versatile dosing and depositing systems for fast…

Product details

To guarantee a professional positioning and storage during cleaning and drying of all machine parts and tools that have been in contact with food during production, DJM developed a specifically designed cleaning trolley. By positioning the parts at an angle, they can be cleaned optimally, while water slips off easily, which speeds up the drying process.

All DJM VacForm, extrusion, diaphragm and dosing/depositing machines can be combined with a vacuum filling unit, resulting in a perfectly integrated production line. A vacuum filling unit feeds the product mix to the machine with an accurate combination of speed and pressure. In combination with a precise control of product size and weight this results in an extremely efficient and economical production process with a high output and an absolute minimal loss of raw material.

All machine parts and forming tools of DJM machines are made entirely of durable stainless steel and are completely removable for quick and optimal cleaning. Attachments are available for both continuous production and portioning, while a quick changeover to other product types is ensured by easily exchangeable forming tools. The portion weight is continuously adjustable during the production process, resulting in accurate weight control and minimal product loss. Programming the PLC control is easy via an intuitive HMI with color touchscreen and clear, menu-driven software.