Forming Technology

VacForm machines are ideal for producing burgers, cutlets, chicken nuggets,…

Product details

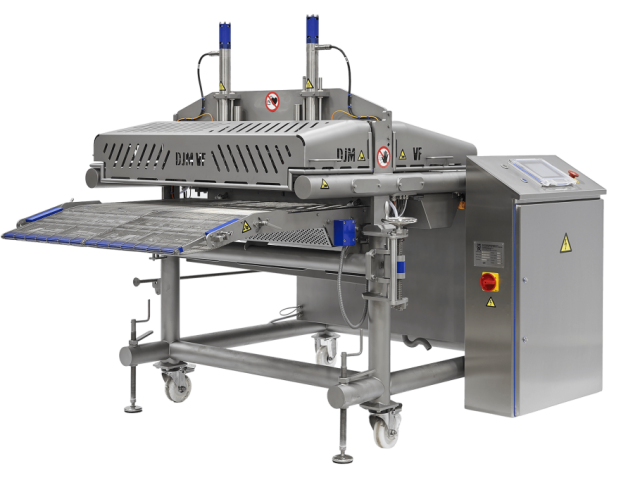

A fast and continuous dosage opening is one of the most important features of DJM diaphragm machines. They can be used to produce round and oval shaped products such as meatballs, potato balls, fish balls and falafel, while more complex 3D shapes are also possible.

Variation in viscosity and temperature is not a problem, so these machines can handle a wide range of product mixes. DJM diaphragm machines are available with up to16 diaphragm dosing heads, realising a production speed up to 150 strokes per minute and a output of over 140,000 products per hour. The patented DJM pressure distribution system ensures extremely precise portion control. Additional machine options include different diaphragm/iris shapes and designs, height-adjustable conveyor belts, stepper system for optimal loading of the conveyor belt, etc.

Configuration

Up to 16 synchronized nozzles

Line width

16” – 400 mm | 24” – 600 mm | 42” – 1,000 mm

Speed

Up to 150 strokes per minute

Product types

Round and oval shaped products