Dosing / Depositing Technology

DJM has developed versatile dosing and depositing systems for fast…

Product details

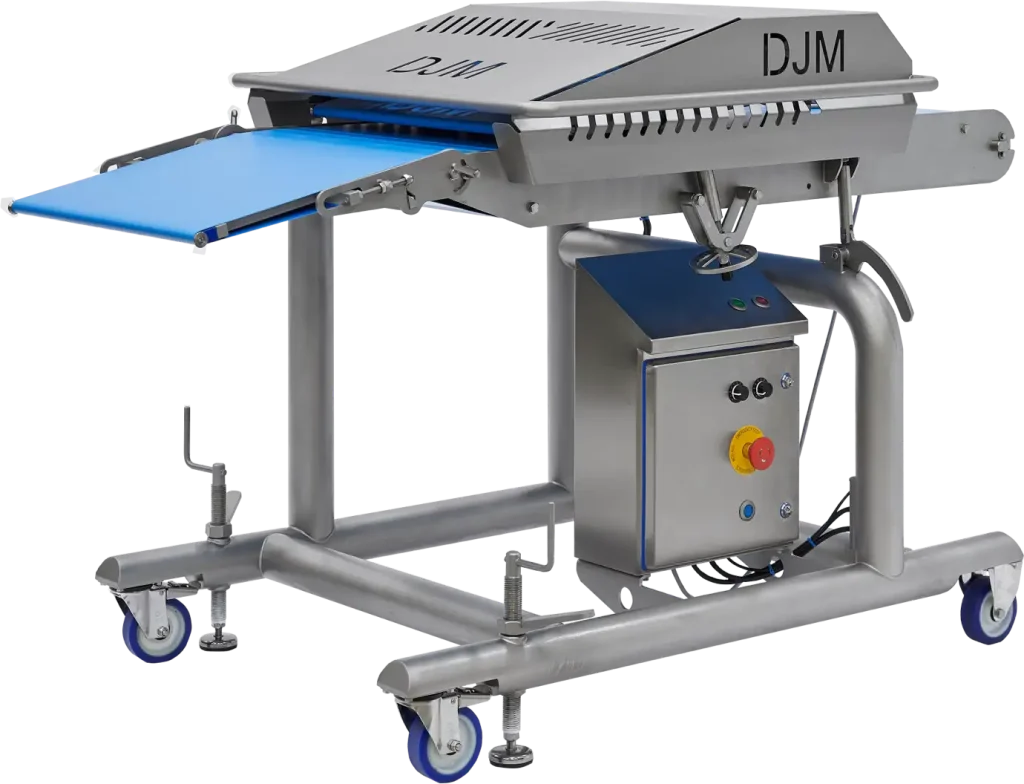

DJM has developed a program of flattening belt machines that are available in different widths and are made up of two motor driven conveyor belts that are positioned at an (adjustable) angle to each other. A precise synchronous belt movement then ensures precisely formed flat products. These machines are widely used for processing different product mixes based on meat, fish or Plant Based Protein. A popular application is the processing of balls or disks into perfectly portioned and shaped burgers.

DJM flattening belt machines are powered by energy efficient drum motors, whose speed can be precisely adjusted by hand. The flattening conveyor belt technology is the ideal next step after forming in which homogeneous or filled products are required as the final product. By processing the products with profile rollers prior to the flattening phase, a unique surface pattern can be created, which makes products look even more attractive in the packaging. DJM’s flattening technology is suitable for meat, fish and chicken products, hamburgers, stuffed cheese products, stuffed meat disks, etcetera.

Line width

16” – 400 mm | 24” – 600 mm | 42” – 1000 mm

Belt speed

6,5 – 39,4 ft/min 2 – 12 m/min

Product thickness

Up to 2,2” – 55 mm

In the brochure you will find more technical data about this machine.

Download the brochure