With an eye to the future

Economical production with minimal impact on the environment has become a pure necessity. Worldwide we must be more economical with energy, but also with raw materials, thus waste reduction is at least as important. DJM engineers are well aware of this. So sustainable and economical production has therefore been one of the most important principles in the development and construction of new machines for years. And it’s clear that this is bearing fruit. The current generations of DJM machines combine unparalleled efficiency with minimal product loss and a small CO2 footprint, thus setting the standard in sustainable production.

Savings on raw materials and energy

DJM machines work with a unique low-pressure system in which the product mix is fed through the machine with a precisely controlled combination of speed and pressure. This accurate parameter control results in significantly less product waste, maximum production yield and high energy efficiency. After all, with less raw material, the same output is achieved as with machines characterized by a higher loss rate. DJM machines clearly use less energy for the same or even better end result. In addition, minimizing the waste stream provides additional environmental and cost benefits. And while we’re on the subject, DJM machines require little or no water during production. This not only results in a cleaner application and an easier to clean machine, but also saves on the disposal and processing of waste water.

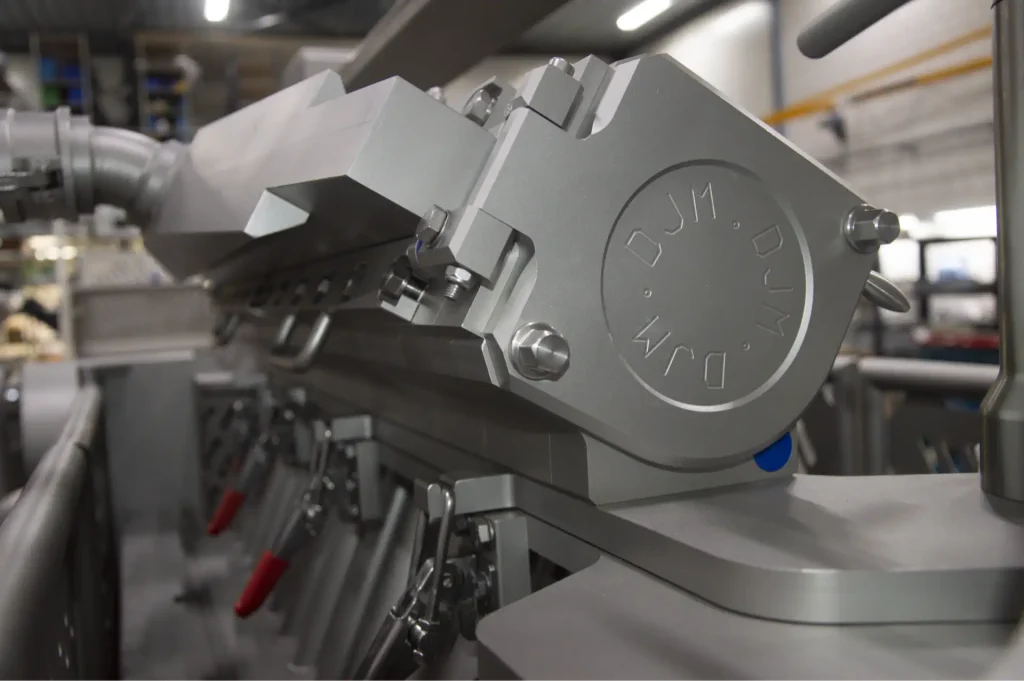

High efficiency drives

All DJM machines are equipped with state-of-the-art electric drives, which has several advantages. Unlike, for example, hydraulic drives that operate on oil pressure, there is no risk of environmental damage due to fluid leakage. Electrical systems are also less complex, require less maintenance and are more compact. If we compare them with pneumatic drives, there are other additional advantages. Pneumatics requires the presence of a compressor installation, whose energetic efficiency is known to barely exceed 17%. The energy efficiency of electric drives, on the other hand, is above 80% and this percentage is still increasing thanks to continuous innovations. Last but not least, DJM machines are characterized by a long service life and low Total Cost of Ownership (TCO). They need to be replaced less quickly and thus also contribute to a more responsible use of (scarce) raw materials. How sustainable do you want it to be?