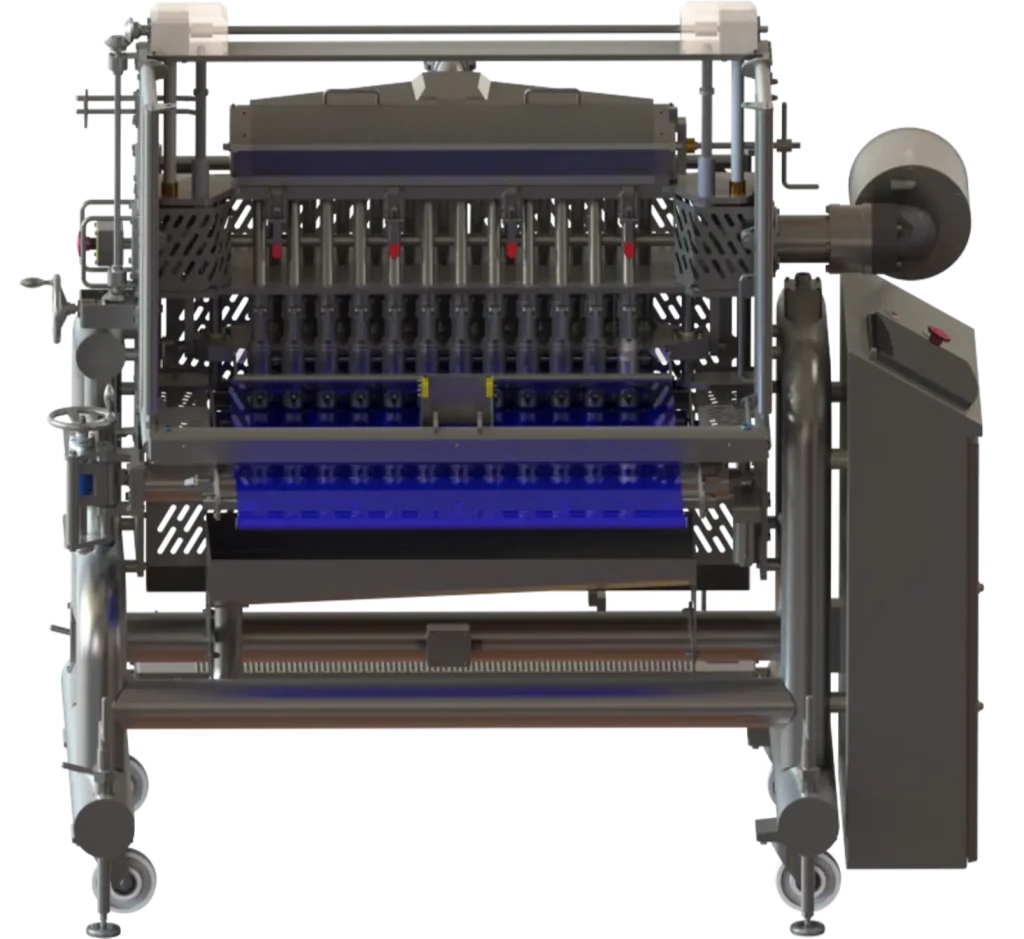

Dosing / Depositing Technology

DJM has developed versatile dosing and depositing systems for fast…

Product details

Unprecedented flexibility combined with high production capacity are some of the outstanding features of DJM 3D extruders. They are ideal for the production of specially shaped filled products such as the ever popular Cheese Chili bites, but also for potato wedges and ‘round shaped’ products.

Ring extruder

DJM’s unique ring extruders produce popular ‘round shaped’ products such as calamari and onion rings and are also the perfect solution for 3D products like scampi bites and snacks with a soft (cheese) filling. The extrusion heads are equipped with the sophisticated DJM quick-change system, making it very easy to switch to other product shapes!

Configuration

Up to 24 synchronized nozzles

Line width

16” – 400 mm | 24” – 600 mm | 42” – 1,000 mm

Speed

Up to 150 strokes per minute

Product types

Specially shaped three-dimensional products

In the brochure you will find more technical data about this machine.

Download the brochure